Reducing Methane Emissions

All energy sources have an environmental effect; from the space they take up to emissions produced throughout their life-cycle. As an example, there is some methane released during natural gas development. But despite a record-setting over the last three decades, the amount of methane emitted into the atmosphere during natural gas extraction continues to drop. Why? Because leading companies are working hard to continuously improve their environmental performance by developing new technologies, collaborating with other companies and colleagues, and implementing best practices that will bring these emissions down to nearly zero.

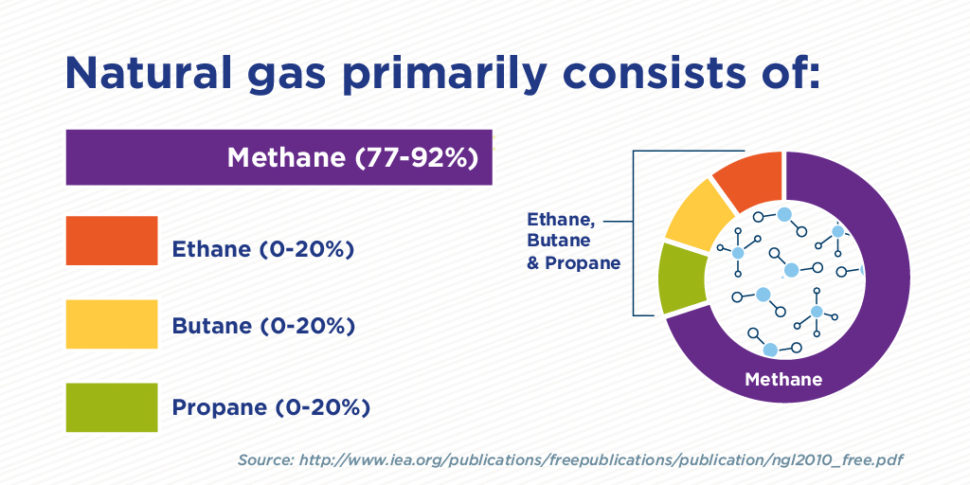

What is methane?

Methane is the primary component of natural gas. With a chemical formula of CH4, methane is made up of four hydrogen atoms and only one carbon atom. The result? For the same amount of energy produced, burning natural gas emits significantly less CO2 into the air than other fossil fuels.

Methane is the clean-burning energy source that fuels our nation more efficiently and cost effectively than ever before. However, methane in the atmosphere is a greenhouse gas. That’s why the industry’s proactive stance on reducing methane emissions that occur during the development of natural gas is so important.

Moving even faster in the right direction.

According to the Environmental Protection Agency, methane emissions from the energy sector decreased 14 percent from 1990 to 2016, while natural gas output increased by more than 50 percent during the same period. And now, new industry programs are bringing companies together to share information and take actions that reduce methane emissions further and faster than ever before.

The Oil and Gas Climate Initiative has committed $20 million to support technologies and businesses that detect, measure and mitigate methane emissions. And The Environmental Partnership, comprised of dozens of the country’s largest natural gas companies responsible for 30 percent of U.S. production, has made a collective commitment to reach specific goals within the next five years that will drastically reduce operational methane emissions.

One of these goals is to create a more airtight infrastructure through the widespread replacement of pneumatic control valves. Pneumatic control valves manage liquid levels, temperature and pressure during the production, transmission and storage of natural gas. Replacing existing pneumatic controllers with low- or zero-bleed alternatives will nearly eliminate a major source of emissions.

Methane leak detection, monitoring, and repair is another area of increased focus. Over the next eighteen months, companies will rapidly increase the use of technologies like optical gas imaging (OGI) infrared cameras to detect and measure methane leaks from a variety of gas industry equipment and will complete necessary repairs more quickly.

Companies are also ramping up internal training programs to ensure employees understand and follow all best practice protocols and procedures to reduce or eliminate methane emissions.

In addition to industry-led initiatives like these, natural gas companies are voluntarily participating in programs administered by the U.S. Environmental Protection Agency, including Natural Gas STAR, and Methane Challenge, both of which promote the use of technologies and practices that reduce methane emissions. One successful practice is a protocol for completing new natural gas wells known as reduced emissions completions, or “green completions.” The process captures gas that would otherwise be released into the atmosphere during the final stage of bringing a new gas well online.

Since the start of these EPA programs, U.S. energy partners have implemented approximately 150 new technologies and practices and eliminated nearly 1.39 trillion cubic feet (Tcf) of methane emissions.

One goal, many benefits.

Controlling methane emissions is not only about environmental health and safety – it’s also good economics. Methane is a valuable commodity; eliminating methane leakage means more natural gas is captured and retained, which can be sold and used as energy.

The increased use of natural gas has reduced carbon emissions, lowered costs to American consumers, and increased our nation’s manufacturing competitiveness. U.S. industrial electricity costs are lower than those of our foreign competitors, giving manufacturers – including producers of steel, chemicals, refined fuels, plastics, fertilizers and numerous other products – a major competitive advantage.

Industry standards and existing regulations on air emissions from EPA and other agencies are empowering the private sector to continue to innovate and deliver more natural gas and oil to customers while improving air quality and protecting public health and the environment without unnecessarily hampering manufacturing and business expansion.

What’s more, the methane mitigation industry has taken off over the past six years, leading not only to cleaner air, but also to high quality jobs in a growing field. Methane mitigation equipment manufacturers and service providers are providing an array of good-paying jobs across nearly all 50 states.

The industry’s numbers are trending in all the right directions. Natural gas production is up while carbon emissions are down, and the industry’s big steps forward in reducing methane emissions are having a broad and positive impact. It all adds up to a win-win situation – for the industry, the environment, the American workforce, and energy consumers everywhere.